Services

Quality

Company

Contact Us

Richards’ FL400 tube laser outperforms all other methods when cutting large quantities of parts. Turning your model file and a length of pipe into a stack of finished parts is what the FL400 does best. A 5‐axis cutting head and 4000 watts of power means fast, clean, high‐definition cutting.

If your project needs enough parts to fill a length of pipe, our FL400 can save your fab shop money. A length of pipe can be processed with one configuration or multiple configurations and run from customer‐supplied material or Richards’ stock.

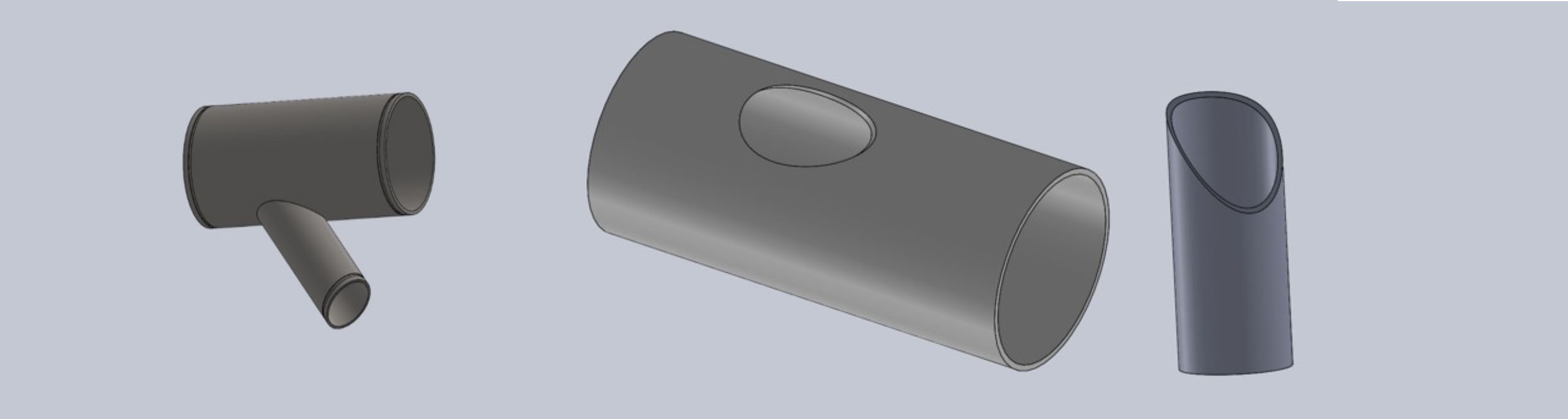

Customer drawings or model files are converted into tube laser files, then nested for maximum yield. The nest is then processed through the FL400 simulator, a program is generated and parts are ready to be cut. Below are images of how the parts shown above are nested in the simulator.

We eliminate time-consuming layout on headers and lateral connections by directly converting a customer’s model files into tube laser cut files. Header connections can be beveled for a stub-on or a stub-in weld spec. Laser-etched alignment marks, part numbers and support locations can be applied per customer requirements.

Many piping contractors are saving money by fabricating their own grooved fittings in carbon or stainless. High cost, long lead times and lack of inventory for these parts have pushed contractors to produce these in-house.

Using parts from our FL400 can help your shop save even more. Tees, reducing tees and reducing Y-laterals can be cut from customer pipe or Richards’ stock, then welded and grooved by your shop or at ours.

The FL400-cut parts reduce lead time and cost, and offer more custom options producing these fittings.

Contact Richards’ sales team and speak with our piping products experts.

Need some mitered fittings for your jacketed piping job? A 12-inch standard pipe is shown with a 15-in radius, to accommodate a 10-inch ell core pipe.

Our mitered fittings are match marked, beveled to your specifications and ready to weld. End pieces can be made any length.

Mixing structural pipe with square and rec tubing, channel, angle and beams are easy work for the FL400.

A support column section is shown with cut knife connections (through the column) and etched locations for beam and channel connections.

The FL400 can cut all these shapes and etch layout locations, as shown. Contact our sales team for a quote!