Use the arrows

to pan left and right. Rollover the hot spots

to learn more.

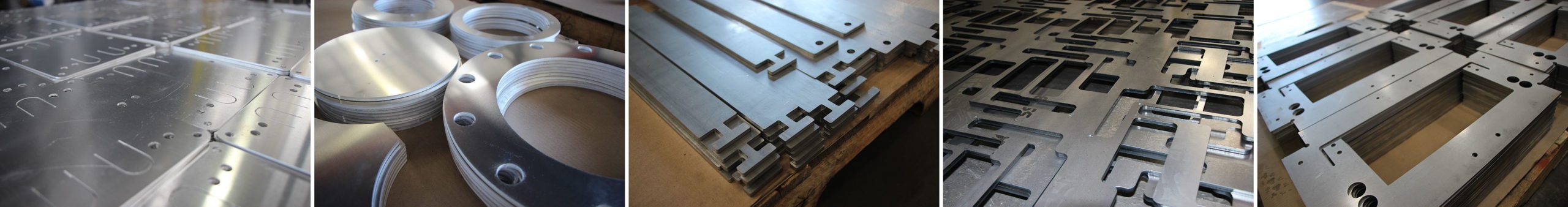

Flat sheet laser cutting is a metal fabrication and manufacturing process that eliminates the need for machining on many engineering jobs, which in turn saves money on manufacturing costs. These laser technologies can produce intricate parts without the need for custom-designed tools.

A thermal-based fabrication process, flat sheet laser cutting is used to cut sheet metal more precisely with a focused laser beam that meets and actually melts the metal. Advanced equipment and laser beam machines allow for improved control and produce very clean edge quality.

With the added benefit of our STOPA automated material storage system as a part of our laser cutting business we eliminate the need for other manufacturing processes and our customers get to enjoy quicker turnaround times on laser cut sheets while still maintaining superior edge quality.

Richards Sheet Metal is on the “cutting-edge” of flat sheet laser cutting capabilities—utilizing four of the most advanced lasers in Utah.

Our advanced flat sheet laser cutters allow for a material thickness tolerances between 0.002″ and 0.010″ on stock up to ¼” thick and 0.005″ to 0.020″ on plate up to 1.25″ thick.

Our 8000-watt Trumpf 5040 fiber lasers, with 4-meter x 2-meter shuttle tables, provides a great advantage when cutting materials thinner than ¼” and redundant capacity for cutting thicker materials.

Our cutting machines, manufacturing processes, and laser cutting service are well-suited for thin materials to thick materials and a variety of sheet metal types.

Use the arrows

to pan left and right. Rollover the hot spots

to learn more.