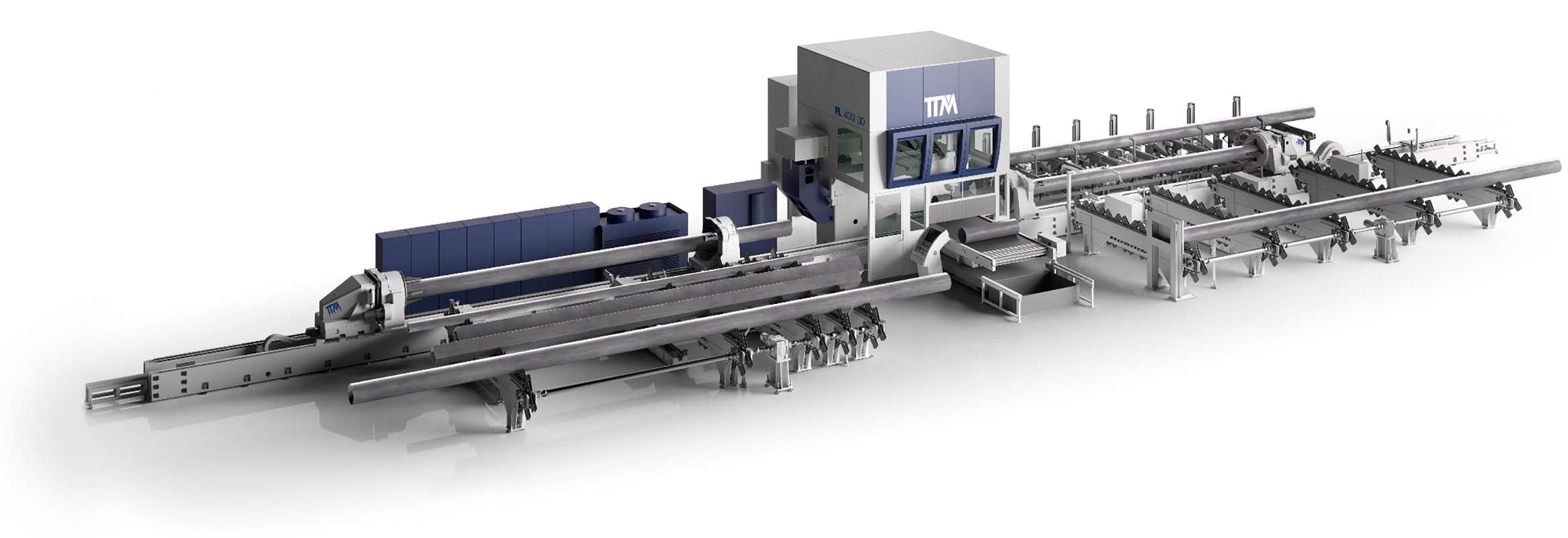

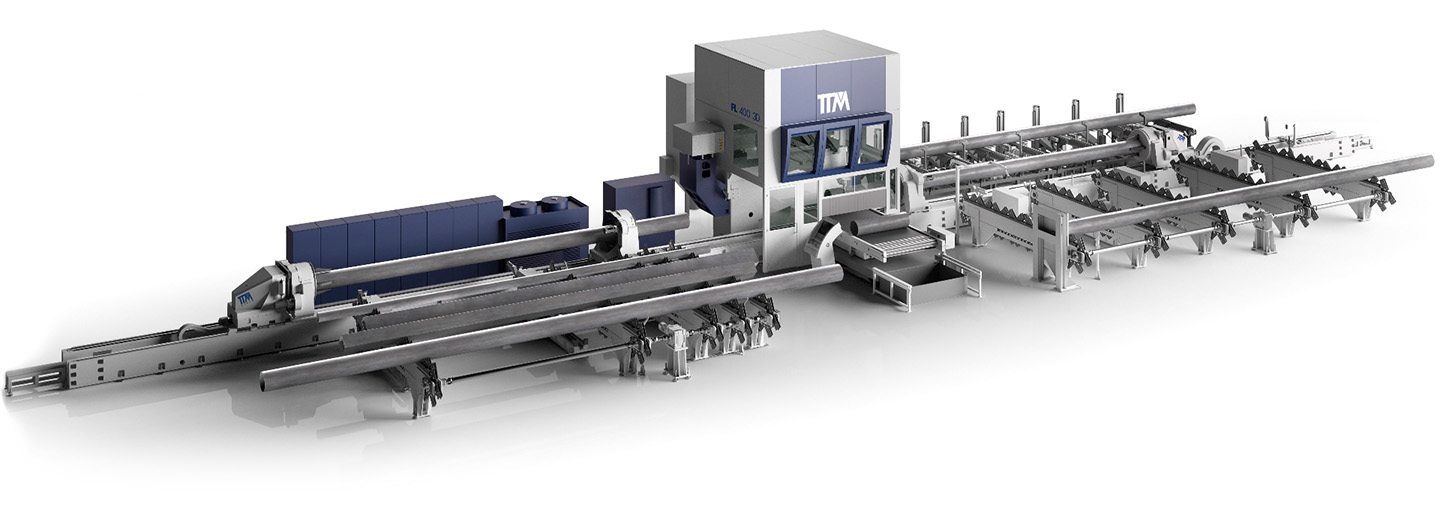

Introducing the FL 400 3D

Use the arrows

to pan left and right. Rollover the hot spots

to learn more.

When you need precision cuts and there’s no room for error, turn to tube laser cutting systems. Used for a variety of industries, including electronics, solar, automotive and packaging, this high-accuracy cutting method is faster and more flexible than traditional cutting options. The process utilizes a focused fiber laser beam to melt sheet metal, cutting clean edges with quicker turnaround times than other methods.

Here at Richards Sheet Metal, we have a 128-foot 3D tube laser cutting machine that can handle up to 16-inches in diameter with a 48-foot infeed length—the largest of its kind west of Kansas City. This addition to our fabrication processes gives us a leg up on the competition, opening our capabilities up to more unique and challenging projects for our clients.

Rollover the hot spots to learn more.

Our tube laser can cut and process a wide range of material, including tube from 1.5 inches up to 16 inches. In other words, if the material fits within a 16-inch diameter, we can handle it. Whether you need metal tubes, steel pipes or even square tubing, our TTM FL400 3D tube laser provides clean, precise cuts unachievable from any other process.

Workpieces from tube laser cutting don’t require any additional processing and fit together perfectly, eliminating the wasted time that sometimes accompanies the secondary construction process. Additionally, after we cut workpieces using our tube laser cutting machine, there is generally very little leftover material. This allows us to streamline our workflow, reduce costs and get projects completed quickly and efficiently.

Our tube laser can handle manually-loaded, wide-flange beam, channel and angle workpieces up to 45 feet long. Additionally, the bundle loader can accommodate round, square and rectangular tubes up to 41 feet long. (Photo features Kevin Jones, VP Tube Laser Group (left); Sterling Jensen, CEO (center); and Dee Roskelley, Sr. VP Technology)

Richards’ new 128-foot-long tube laser can handle manually-loaded workpieces—including wide-flange beam, channel and angle—up to 45 feet long. The bundle loader can accommodate round, square and rectangular tubes up to 41 feet long.

Do you need to add channels? We can do that. Need a bend? We can do that, too. The flexibility of tube laser cutting allows us to process round, square and irregular profiles.

Tube laser technology greatly reduces production time from hours to minutes and minutes to seconds, which results in quicker turnaround times for our customers, and facilitates improved welding and fit-up—and lower costs for our clients. Our tube laser lets us perform V bevels, Y bevels, X bevels and K bevels. No matter the type, we can control the degree of the bevel from 10 to 45 degrees, increasing our capabilities and precise, high-quality outcomes of your project requirements.

Use the arrows

to pan left and right. Rollover the hot spots

to learn more.